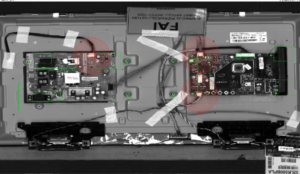

The entire project includes the supply of 9 complete stations for vision inspection of TV components. The client is one of the largest manufacturers in Poland. After ordering the first pilot station in 2016, testing it and optimizing it, the customer decided to order 8 more stations, automating vision inspection on all 9 production lines at the plant in Poland. With the use of manual linear shifts, it is possible to smoothly adapt the station to changing types of receivers – i.e. different barcode locations and different sizes, thicknesses of passing TVs.

Scope of control:

- Presence of mounting screws

- Correct position of cable mounting tapes

- Checking free areas and VESA pins (no cables near them)

- Proper fastening of connectors

- Proper fastening of LVDS tapes

- Correctness of cable routing

The use of automated vision inspection stations eliminates errors that arise from imperfect inspections performed by employees. It also prevents the costly process of disassembling receivers when a defect is detected on one piece from a given production set – thanks to the fact that each receiver has a photo stored on the server, it is possible to check all features of the assembly (even those not within the scope of automatic inspection by the workstation ), previously the manufacturer was forced to re-inspect the entire series.